With the constant pursuit of people's living environment, the demand for wall switch products is also on the rise year by year. In the dazzling market, how importers can reduce the procurement cost from the product material has undoubtedly become a great concern for many buyers. Different markets have different needs, so the following are two perspectives on the external and internal materials of wall switches, to talk about the material characteristics and price differences, which will certainly allow you to reap the rewards of the procurement process.

Selection of different external materials

The usage of switch and socket panel material, needs to consider these requirements standards: flame retardant, insulation, impact resistance. Flame retardancy goes without saying. The panel is fixed to the wall and is affected by different sites. The temperature in kitchens and areas with direct sunlight will be relatively high, also because of the problems with the electrical products themselves, causing short circuits, sparks and other safety hazards. If you choose the panel that is not from the formal channels of procurement, then its flame retardant will be greatly reduced because of the problem of inferior materials. After using several times, the light panel will be deformed, or even more severely, melting, which in turn will cause greater safety hazards. Insulation is also an important issue that can not be ignored for panel material. The quality of Impact resistance is also significant for the aesthetics and service life of the product. If the material itself does not have good impact resistance, with poor quality materials instead of the common rubberwood and PC class on the market, then the direct consequence is that, for a short time, the switch panel is cracked, affecting the aesthetics, not to mention the resulting safety hazards more worrying. The subsequent series of after-sales problems will also make you anxious and angry for a long time.

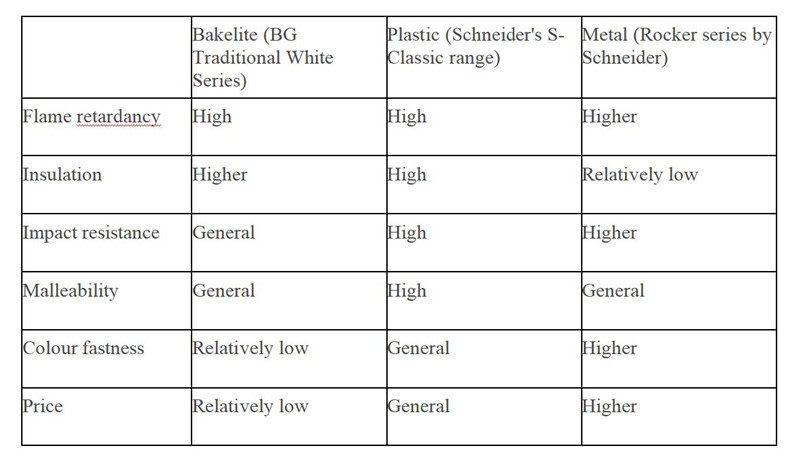

Compare the three main panel materials on the market: bakelite, plastic and metal. Of course, here to highlight that the premise is the need to find a reliable manufacturer, to ensure that the procurement of raw materials is to take the formal way and purchase to the new material, rather than using the old material to good. Then about how to find a reliable manufacturer (here not to expand), and in the next article we will talk about this aspect of the topic. Moving on to the analysis of the three main materials as follows:

1. Bakelite: pressed out of what we often call urea formaldehyde molding compound. It can be made into various shapes by using moulds for people's use. The properties of bakelite are good insulation properties, high strength and low deformation. It was the most common material used in the early years of switched socket production and is relatively inexpensive. The colour of bakelite products can be relatively homogeneous, generally white, and can easily yellow and become old under daily exposure to light and UV light. BG's traditional white series of wall switches, including the rounded and square corner series, are mostly made of bakelite. And the data from online sales in the Middle East market, shows that these products still have a certain market share.

2. Plastic: mainly refers to PC or ABS material. It is the mainstream material in the market at present. This material has high strength, good elasticity, impact resistance, and high-temperature resistance, high flame retardancy. Compared with the bakelite, the weight of plastic will be lighter, and the price is slightly higher than the bakelite. However, the plasticity of plastic is good, the stability of the colour is good, and the choice of colours is not so homogeneous. Although the price is slightly higher than that of bakelite, the longevity and aesthetics of the plastic are more than that of bakelite. Schneider's S-Classic switches are made of PC, which gives them a softer line and is not as heavy-duty as the bakelite switches, but the obvious advantages of the material itself make plastic, especially PC, a better choice. The S-Classic range of switches, especially those made of PC, is gradually gaining market share.

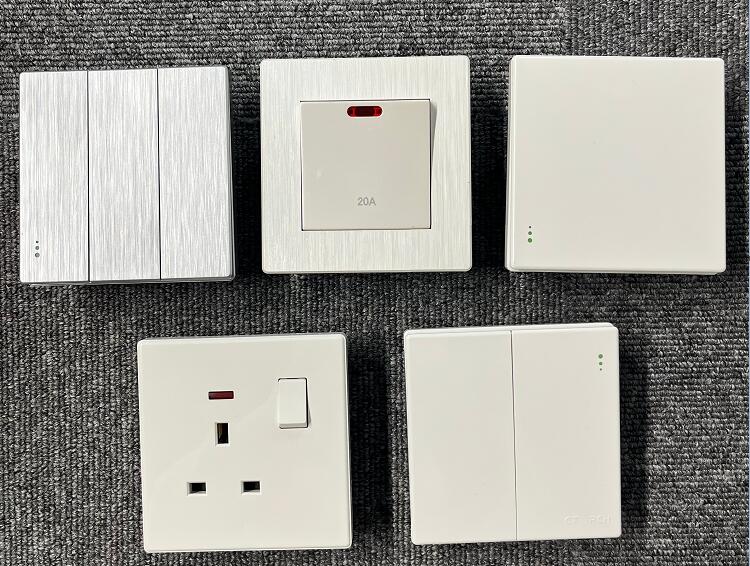

3. Metal: generally made of stainless steel, aluminium, zinc alloy etc. Metal panels are not only durable but also have a metallic lustre and texture. There is no need to worry about metal conductivity and safety problems. The metal switch panel will be added to the internal plastic protective cover, thus ensuring the safety of the use of the problem. The texture of the material itself makes it visually very modern and, of course, the most expensive of the three materials. However, the metal switch is undoubtedly the most resistant to ageing and the most durable of the three materials. For example, the UNICA series is made of aluminium and has a unique metallic lustre that makes the whole product range visually striking. The Rocker series from Schneider, for example, is also available in aluminium and stainless steel. As can be seen from the pictures, the unique glossy metallic finish shows the high-end quality of the products and, in contrast, a more modern and technological feel.

(Comparison of the properties of glued wood, plastic and metal)

In summary, if the market is very price-sensitive and there is not a high demand for product appearance, you can choose a bakelite switch. For a more price-sensitive market with a certain demand for product appearance, consider plastic switches, which currently have a relatively high market share. For customers with a certain degree of price acceptance and the pursuit of quality, you can try metal materials.

Different internal materials to choose from.

After introducing the material of the panel, the choice of internal material is also very important.

From the three parts: the contacts, the connected metal parts and the backplate.

1. Contact: Pure silver is the best contact material. It can ensure the sensitivity of the product very well. Our regular products are made of this material. BG and Schneider's mid-range and high-end products, most of which use pure silver contacts, are more sensitive and have a better service life.

2. Connection metal: Tin phosphor bronze called purple copper, is the best metal connection material. Socket copper piece using tin phosphor bronze material, has high strength, good plasticity, with good electrical conductivity and is not easy to deform. However, the price of phosphor bronze is higher than ordinary brass, so customers who have their own budget for the price can consider ordinary brass. The internal connections of Schneider switches are made of tin-phosphor bronze, which gives the product a high conductivity and low heat content.

3. Back cover: PC and ABS materials are the most used materials for back covers. Their flame retardancy and impact resistance are good, and they can meet the safety requirements of regular current wall switches and sockets. However, for high power sockets such as 20A and 45A, you can also use nylon material with better flame retardant properties, but the price of nylon material is slightly more expensive. When looking at Schneider's products, the highest proportion of PC is used.

In summary, sterling silver contacts, tin-phosphor bronze connection pieces and nylon backing are the optimum internal material mix. However, given the price constraints of some customers, other materials as described above can be substituted to meet the price requirements.

Our company has also developed many collections of wall switches in these three main materials.

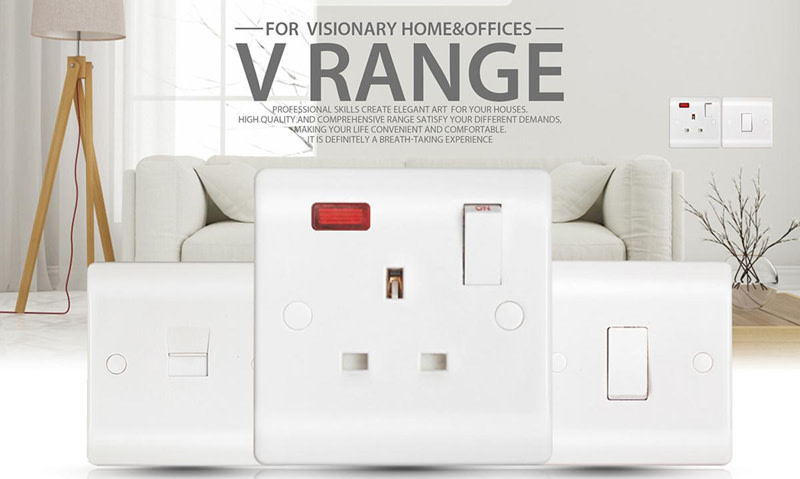

For example, the V series has a classic look with a bakelite panel with a graceful curve on the upper and lower part of the panel, giving the product a softer and less monotonous look. Combined with the above-mentioned feature of bakelite products being in a single colour, the series is only available in white. The popular one-two-three-four openings in the market are all covered in our range, with different switches available and with single or double control. In addition to switches and socket panels, we also have adjustable switches, network and telephone line panels available.

The R30 series is made of PC panels. Compared to the previously mentioned V series, the R30 has more colour options, adding beige, silver, rose gold, gold and coffee to the white. There are more options for matching different decoration styles. For the Middle East market, the feedback on gold has been very good and more and more importers are experimenting with colours that are different from the traditional white. Of course, the R30 range also includes 1 gang,2 gang, 3 gang, 4 gang. And different switches can be selected for single or double pole. In addition to switches and socket panels, we also have adjustable switches, network and telephone line panels available.

The T series is made of metal panels, which has a superb modern feel. The whole series has an excellent texture and the unique gloss of metal allows the products to show a different aesthetic in a different light. The Metal range is currently available in 2 colours, Brass and Stainless Steel.

For more information, please feel free to contact us and ask for advice.