As a necessity for everyday electricity use, extension sockets involve safety in use. Many countries have strict requirements for the structure and materials used in the local production or import of extension sockets. For example, the socket must be equipped with a childproof safety door. The cross-sectional area of the copper wire must be specified according to the length of the power cable. And the shell must be made of flame-retardant material in order to avoid fire. There is a component called an overload protector in the extension socket, which is also intended to ensure safety in use. There is no mandatory requirement for this part of the market to be configured, but if it is, the cost will rise. If you want to start importing extension sockets for sale in your market, then you should think about whether it needs to be equipped with an overload protector.

The function of an overload protector

To determine if an extension socket needs to come with an overload protector, you first need to know how overload protection works and to a protective role in an extension socket.

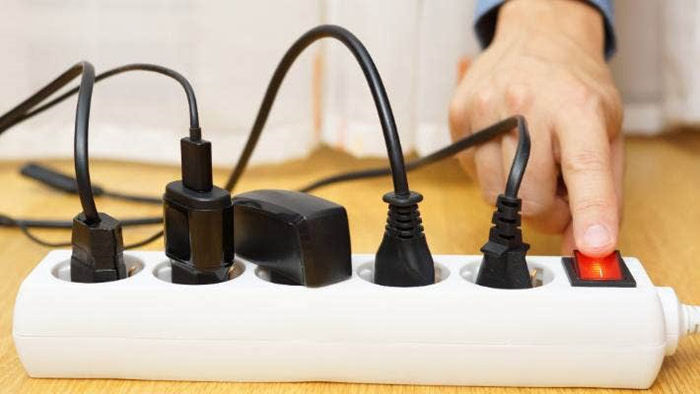

Extension socket is a single socket power expansion equipment, a single power output port to expand into a multi-terminated power output hole, to meet the simultaneous use of a variety of household appliances power supply. However, there is a limit to the amount of electrical power that can be loaded. For example, the total power of an electrical appliance marked as 13A, 250V~ cannot exceed 3250W (12A◊250V). Once the load capacity has been exceeded, it is easy to cause the charging equipment to fail or the wire temperature to rise and fire to occur. It is not always possible to calculate the total power of an electrical appliance, so overloading an extension socket is inevitable. To ensure safety, some of these sockets are equipped with overload protectors. When the load on the extension socket exceeds its rated maximum power, it will automatically cut off the power supply to protect electrical property and personal safety.

If this alone does not give you a sense of the effect of the overload protector on the extension socket, you can refer to the following experiment.

First, we use an extension socket that is 13A, 250V~, maximum load capacity of 3250W, without overload protector, as sample No. 1. In the beginning, we connect a 1500 watts electric iron into sample NO.1, the sample reacts nothing. Then connect a 1000 watts of electric rice cooker, extension socket and appliances are normal use. But when connected to a 1200 watts electric heaters and three electrical appliances work a few minutes later, we use a thermometer to measure the extension socket shell surface temperature. It turns out that the temperature is higher and higher. If you continue to plug in other high-power appliances, the temperature will rise rapidly.

Secondly, under the experimental situation, when flammable objects such as paper towels, sponges and cotton cloths are used to cover the extension socket, the temperature rise accelerates and can even reach the ignition point in a short time, giving rise to ignition hazards.

Finally, we use the same rated power of 3250W but with overload protection extension socket, the same in turn access to several appliances, 3 appliances at the same time power working about 5 seconds, the extension socket automatically powers off. Turn off the power switch, remove one of the appliances, wait for 5 minutes or so for the temperature of the extension socket to return to normal, reset the overload protector button, then turn on the power switch, the extension socket continues to supply power normally.

The above experiments show that a qualified overload protector can cut off the power supply in case of overload and prevent the extension socket or the appliance from heating up and causing a fire hazard. When the loading power is normal, the power supply can be restored normally.

The difference between overload protector, surge protector and over-temperature protector

1. Overload protector

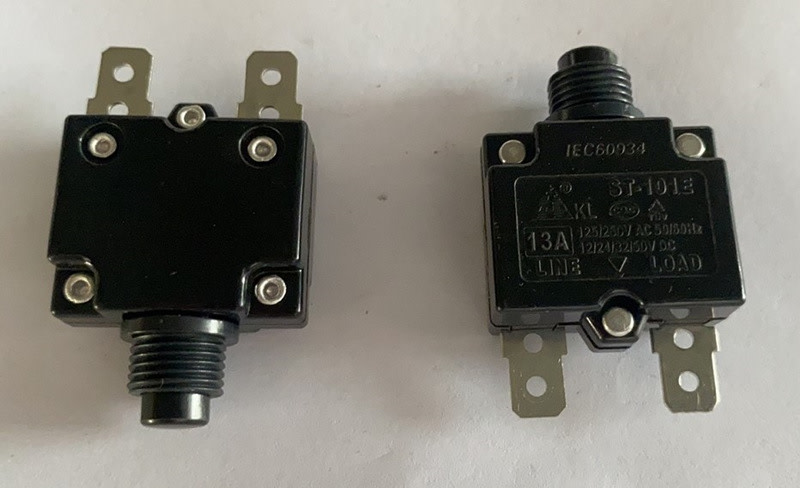

The overload protector on the extension socket is essentially a passive-driven thermal protection relay, usually installed on the side of the extension socket near the power cord. There will be an inline button on the side of the extension socket housing that is slightly raised. The overload protection switches all have a maximum current allowed for safe operation. When the load on the extension socket is too high, for example over 15A, the overload protection switch will overheat and pop the button up automatically, achieving a complete power failure. So sometimes we also say that the overload protector is actually an overcurrent limit. After removing the overload, simply press the button of the overload protection switch back manually to achieve a reset, and the extension socket can be used normally.

2. Surge protector

Surge protection, also known as lightning protection, is an electronic device that provides safety protection. Circuits in lightning strikes or in the connection, disconnection of high power appliances often produce a very high operating overvoltage. This transient overvoltage (or overcurrent) called surge voltage (or surge current), is a transient interference. Surge protectors can instantly absorb surge voltage (or surge current) to protect electrical appliances. Surge protectors are generally very expensive, and the extension sockets currently on the market advertised with surge protectors do not really surge protectors.

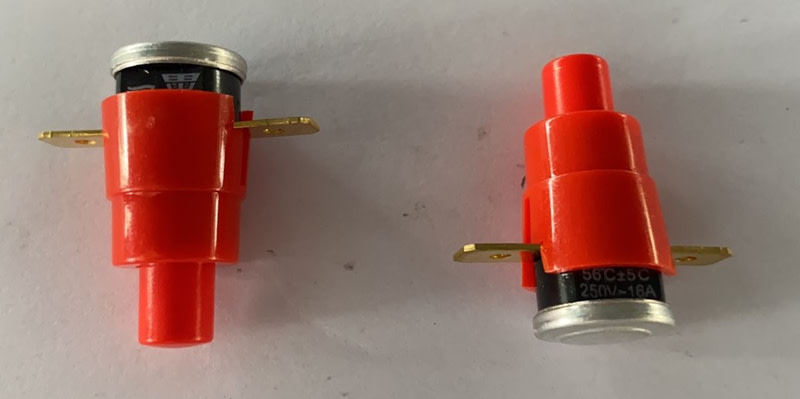

3. Over-temperature protectors

The over-temperature protector is a temperature-oriented component that monitors the internal or surface temperature of the product. When the heating index exceeds the technically specified safety value, the over-temperature protector controls the disconnection of the circuit, thus acting as temperature control. When the circuit cools down to a certain temperature, it continues to be energised for normal use.

When discussing safety protection devices for extension sockets, it is common to get these three confused. But the three protector elements are not used for the same purpose and monitor different parameters. Overload protector for the rated power, surge protector for the instantaneous voltage (instantaneous current), over-temperature protector for the heating index.

The requirements of the extension socket overload protector in each country

If you are a supplier, importer or distributor of extension sockets in your local market, etc., you should not only know the working principle of the overload protector, the purpose of using it, the quality and cost of the product, but you should also know the technical requirements for extension sockets in your market.

Saudi Arabia's newly revised regulation SASO 2815:2021 requires overload protectors for all units and multi-way removable extension sockets. Previously, the requirements for overload protectors on extension sockets entering the Saudi market were that overload protectors were mandatory for four ways, five ways and above ways sockets, while two ways and three ways sockets were basically without overload protectors. The updates to the SASO 2815:2021 regulation on overload protectors need to be noted by product suppliers in the Saudi market.

In addition to Saudi Arabia, countries such as Russia, South Korea and Vietnam also have mandatory requirements for commercially available extension sockets to be equipped with an overload protector.

If there is no mandatory requirement for overload protectors in your market and you do not equip it to balance costs, you should not ignore the safety of the end-customer's extension socket. Extension sockets without overload protectors should be clearly and distinctly marked with a reminder of the maximum related load power and the total power of the connected appliances. In addition, the quality of the raw materials used in other components must be even higher.

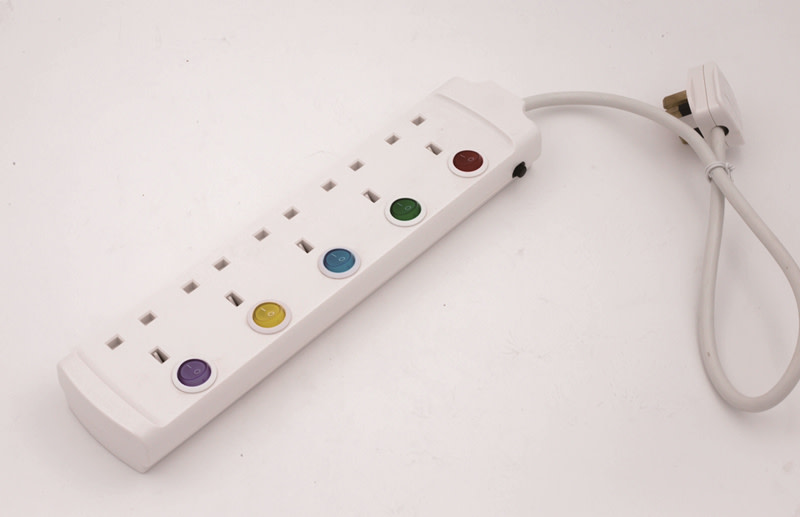

The Homebest extension socket is made of PC/PP material, which is tested and certified by the BV agency to be flame retardant at 750°C to prevent fires from occurring. The interior is made of H62 brass, which is a higher quality material than H52, with thicker and higher copper content, exceeding the requirements of SASO 2815, GSO2117, IEC 60884 standards, for better conductivity and reduced heat generation. The VDE certified power cord is made of oxygen-free copper wire with 99.9999% copper content and a cross-section of 1.50mm² (S=πr²=3.14*(0.196/2)²≈0.03mm², 51 copper wires per cord, total cross-sectional area S=0.03*51=1.54mm²), which enhances the load-bearing capacity of the extension socket and allows it to withstand higher currents without heating up easily. The high quality of the components and the quality control of many aspects are essential to ensure the safety of the extension socket.