After receiving requests from several private economic sectors and international organizations to extend the implementation of hazardous substances control for electrical and electronic equipment, SASO decided to extend and start mandatory RoHS control for different products in phases on December 16. Compared to the original earliest implementation date of January 5, 2022, so that buyers have more time to interpret and coordinate the supply side and sales side of the transition period for this regulation.

Below we explain the latest SASO control content on RoHS through the three major aspects: comparing the product scope, the original and post-phased time, and testing requirements and considerations.

I. The range of products that need attention.

1.Large and small home appliances.

2.Information and communication technology equipment.

3.Lighting equipment.

4.Electrical and electronic tools and equipment.

5.Games, entertainment equipment and sports equipment.

6.Monitoring and control tools

The above products are covered by electrical and electronic equipment and spare parts. RoHS regulations ensure product quality and protect the environment and consumer health and safety through the determination of the percentage of hazardous substances in electronic and electrical equipment and its accessories.

II. SASO's original time for the implementation of RoHS compared to the time after the phase-in.

In the SASO Compliance Steering Committee meeting held on December 5, 2021, a number of private economic sectors and international organizations in the field of electrical and electronics, combined with the specific content of RoHS, proposed the extension and phased initiation of mandatory RoHS control for different products. The time comparison after the extension is as follows, and purchasers of related products need to pay special attention.

1. Large and small home appliances.

(1) Small household appliances, the implementation date from January 5, 2022; delayed to July 4, 2022.

(2) Large household appliances, the implementation date from April 3, 2022; delayed to October 2, 2022.

2. Information and communication technology equipment.

Implementation date July 1, 2022; delayed to December 31, 2022.

3. Lighting equipment.

Implementation date September 27, 2022; delayed to March 31, 2023.

4. Electrical and electronic tools and equipment.

Implementation date of December 25, 2022; delayed to June 29, 2023.

5. Gaming and entertainment equipment and sports equipment.

Implementation date of March 23, 2023; delayed to September 27, 2023.

6. Monitoring and control tools.

Implementation date June 19, 2023; delayed to December 26, 2023.

Through the above time comparison, we can see the time after the extension compared to the original implementation time, where there is a delay of about 6 months. As a purchaser, on the one hand, for the goods of the completed, not meeting the requirements of RoHS regulations, purchasers need to complete sales within this period of time. For the large number of inventories, it is recommended to take a discount concession, as soon as possible to complete the batch of goods sold. On the other hand, on the supply side, new orders placed need to emphasize with the supplier the testing requirements of the product. If the supplier in the process cannot meet the demand or price, to buy time to negotiate with the supplier or find a supplier who can standby.

III. The test requirements and precautions.

As a Saudi Arabia importer, you need to understand the testing requirements of RoHS testing, as well as precautions, in order to better understand the product and correctly audit the relevant data after the supplier sending the report.

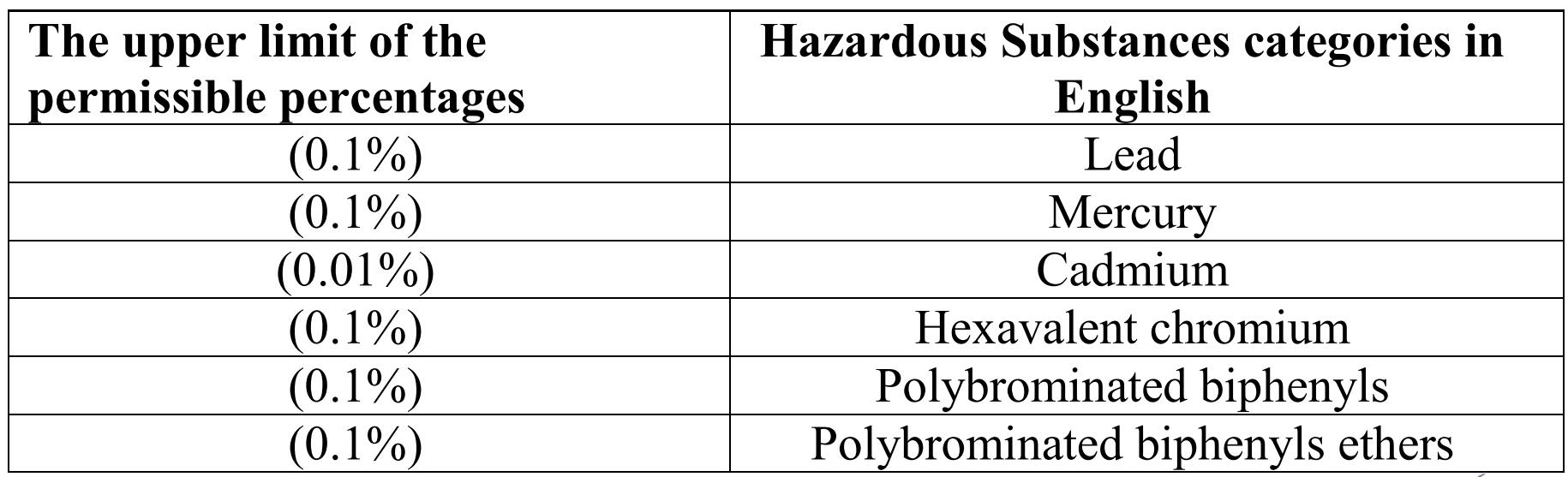

1. The content of Saudi Arabia test is basically the same as the six items of EU RoHS. You can refer to the following table, as the main test hazards are lead, Mercury, cadmium, hexavalent chromium, polybrominated bio benzene, polybrominated diphenyl ether. The maximum allowable percentage of sample testing is referred to the table below.

2. With the reference of the test content and data limits as above, we need to pay attention to the following points in the specific components of the product.

(1)The plastic parts of electronic and electrical products.

Pay attention to the shell, protective door, protective cover shell, switch body, pressure plate, as the material of these parts are mostly PC, PP, flame retardant PA66. Pay special attention to whether the raw materials comply with RoHS, whether there are hazardous substances exceeding the standard for mixing color powder color plastic parts.

(2)Hardware.

These parts are made of brass, 59 copper and purple copper. From the purchase of raw materials to the later surface treatment of materials, pickling and electroplating, we should pay attention to the content of hazardous substances.

(3) Standard parts.

Standard parts in electronic appliances, such as some screws, springs, also need to notify the supplier to pay attention to whether the material itself exceeds the standard, as well as in the post-surface treatment, pickling, plating process of hazardous substances exceed the standard.

(4) Packaging.

Product packaging includes stickers, paper cards, liners, instructions, color boxes, outer boxes of paper products, as well as single and double blisters, PVC boxes of PVC materials, and the final box packing tape is also in the range of parts. Paper products will usually have a lot of printed content, and printed ink composition and the material of the surface lamination are involved in the risk of exceeding the standard of hazardous substances.

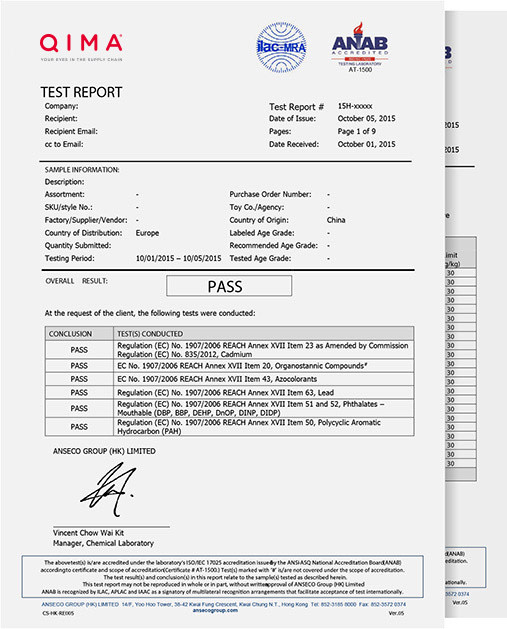

3.The laboratory will issue a test report after the completion of the test. As a purchaser, when you receive the supplier's test report, you need to check from the following points.

(1) See whether the agency that issued the report is authoritative.

Testing organizations are generally displayed at the beginning of the report, such as SGS, TUV, QIMA, INTERTEK, etc.

(2) Look at the report number.

In the same report, no matter how many pages, the report number should be the same. If the number is different, then the authenticity of the report is questionable.

(3) Look at the date of the report.

RoHS report is valid for one year. If the supplier has provided the report has expired, it does not have practical significance.

(4) Look at the company name and address of the test unit.

This is well understood. If the supplier took someone else's certificate, the actual production has no meaning.

(5)Look at the items and values of the test, and the results.

(6)To see if there is the signature and seal of the person in charge of the organization.

For more information about the implementation of RoHS control in SASO, you can enter our website https://www.hbsocket.com/, and you are also welcome to communicate relevant information by private message.