More and more importers are sourcing LED lights from China, and there are more and more styles and types of LED lights. Today we're talking about the minefields that importers of LED floodlights often step into. If you import products that happen to have these types of products, don't miss them.

一、 Housing material and heat dissipation.

Commonly used housing materials of LED floodlights are metal and plastic. The metal here mainly refers to aluminium and zinc alloy. Generally speaking, the heat dissipation of metal is significantly better than plastic, and the quality is heavier and the product texture is very good. The disadvantage is that the cost of metal is relatively high, and importers with a limited cost budget, will choose to reduce the cost to use plastic housing.

Putting aside the difference in materials, here is another word about how to see the thermal performance of the case under the same material premise.

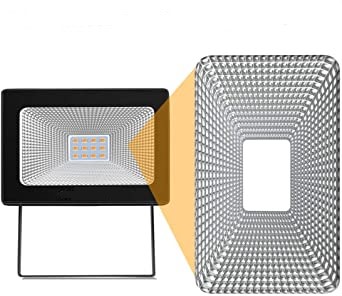

First of all, we can see from the diagram below that the aluminium fins are used to increase the cooling area (the fins here refer to the densely arranged part of the picture). We can see that the higher the density of the fins, the larger the contact area with the outside when the internal heat is dissipated. It means that the larger the cooling area, the better the cooling performance of such a design, but the high density of the fins also means that the higher the cost of the material used. Therefore, it is a real issue for importers to consider when purchasing, to grasp the acceptance between price and fins material.

The metal housing has good heat dissipation performance and is generally used for high-power LED products. Plastic does not bear the heat dissipation function to only do small power, because heat dissipation can only be achieved by the lamp board (an aluminium substrate).

Importers need to pay some attention to the heat dissipation performance of the product because this performance is directly related to the service life of the product. Regarding to the LED light source, the more power it has, the more heat will be emitted. If heat is not dissipated in time, it will lead to internal components shorter service life, because of high working temperature. Many importers focus on price at the beginning and ignore the suppliers' cutting corners in this part of heat dissipation, which, in the end, causes a rise in the rate of consumer complaints about the product.

二、The material of the frame and the development trend.

The material of the frame has 2 kinds: aluminium frame and plastic frame. From the above analysis of the housing material, it is easy to see that the material quality and price of the aluminium frame, are higher than the plastic frame. Towards the same material, the heavier the quality, the higher its price. As the frame is far more decorative than functional, many importers will choose a plastic frame, painted and coloured. Currently, in order to save costs, some suppliers even remove this part of the frame directly and the lampshade is directly attached to the housing in a fixed way.

However, floodlights are often used in outdoor locations such as large operating fields mines, building outlines, stadiums, overpasses, monuments, parks and flower beds. Generally speaking, metal outer frames are more resistant to the natural environment than plastic outer frames. And if the natural weather conditions of the environment, where they are used, demand a high degree of material resistance to ageing, then metal is recommended. Plastic frames, even with protective paint, will age faster than metal under the same conditions.

When importing, if the importer is price sensitive and needs to control costs, the cost of the frame can be within the range of the deletion. But not the cost of the electronic parts should be trimmed.

三、 The reflector (reflector cup) materials and selection.

Reflector (reflector cup) refers to the long-distance spotlighting reflector with the use of point source bulbs as the light source. It is usually cup-shaped, commonly known as a reflector cup. The usually luminous angle of LED light source is about 120 °. In order to achieve the desired optical effect, reflectors will sometimes be used to control the light distance, light area, light spot effect.

There are two common types of reflectors (reflector cups): metal and plastic.

Metal reflector: It needs to be stamped and polished. It has the deformation memory (Under certain conditions, they will return to the state before the deformation). Advantages: low cost, temperature resistance, commonly used in low-grade lighting requirements of lamps.

Plastic reflector: The product needs to be completed in a single demoulding, plastic moulding and then plating effect, high optical precision, no deformation memory (Under certain conditions, it will not return to the original state of the material.). Moderate cost. Commonly used in the high-grade lighting requirements of the lamps with not so high temperature.

Importers should pay attention when purchasing LED floodlights. If the wattage of LED floodlights is relatively high and the heat generated by the light-emitting is large, then importers need to choose a metal reflector with good temperature resistance. If the wattage is not high and at the same time the positioning of quality is high, then a plastic material can be chosen.

四、 The material and choice of lampshade.

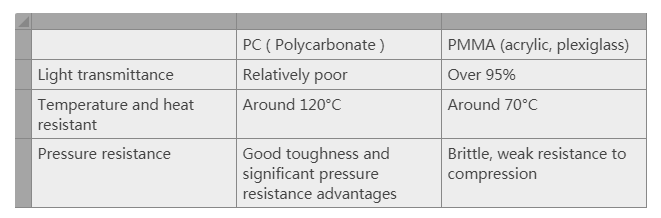

Materials of LED lampshade are generally common PC and PMMA (acrylic, plexiglass).

PC ( polycarbonate ) light transmission rate is the highest, but PC is easy to ageing, yellowing, especially under exposure to ultraviolet light. PMMA ( polymethyl methacrylate ) is easy to soften when reaching 70℃, while PC 120℃. Thus, PC is more temperature and heat resistant, with wider working temperature applications.

(Comparison of the performance of PC and PMMA lampshades)

Through the above analysis, we have gained an in-depth understanding of the composition of an LED lamp from its structure. When purchasing LED lamps, importers should consider the trade-off between materials and price in different structures from the specific parameters of the product, so as to import cost-effective LED products, rather than blindly seeking low prices.

In next articles, we will also explain LED lamps from the perspective of electronic parts, so don't miss it if you are interested in.