LED panel light is becoming more and more widely used in the market as the technology matures. Especially the 600*600 style panel light is widely used in hotels, offices, supermarkets and other places as a commonly accepted type in various countries. How to purchase cost-effective panel lights in factories? It is the basis to know the materials used for its components, and be familiar with its using effects and disadvantages.

The Choice of Direct Light and Side Light

The panel lights currently on the market are mainly divided into direct luminous panels and side luminous panels.

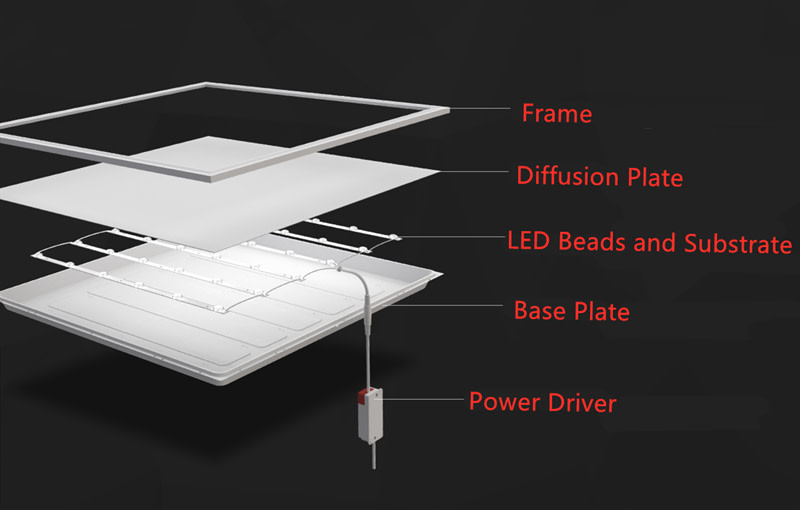

Direct luminous panels use the light-emitting angle of the LED beads to a reasonable spacing evenly arranged on the substrate plate, with the diffusion plate and the installation height to achieve the ideal light effect. The direct luminous panel light focuses on high brightness, with 595*595 40W specifications reaching 4000lm, high luminous efficacy products, replacing the traditional grille light panel. The luminous efficiency is more uniform and the brightness uniformity can reach above 0.9. The process requirements are relatively simple. The distance between the lamp beads and the diffuser plate must be relatively large because of the large interval between the lamp beads so that no dark areas are formed when the light is on. The panels are thicker, usually reaching a thickness of around 24-35mm.

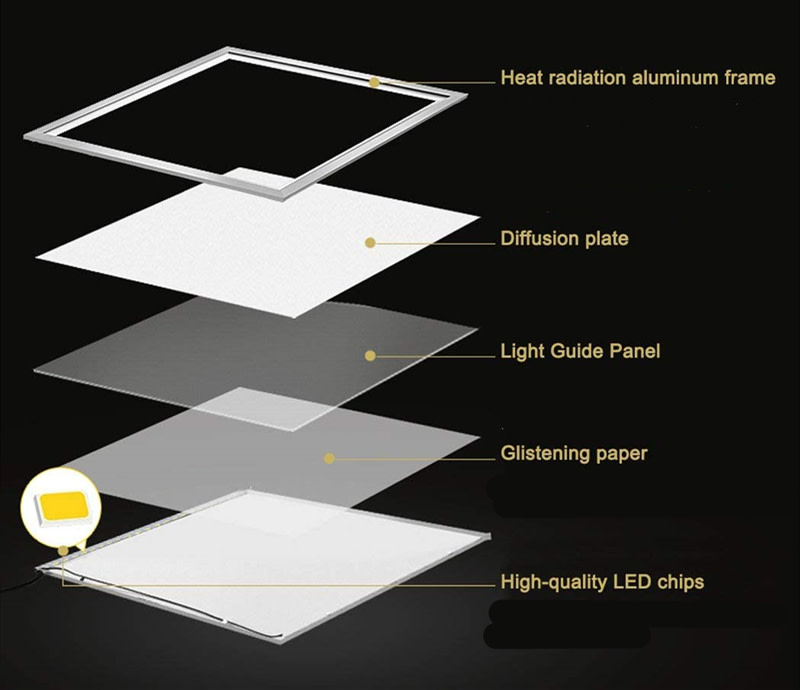

The side luminous panel has a light guide plate that the direct luminous panel doesn’t have. LED beads are inlaid around the panel. And according to the layout of the LED beads and the angle of the beads, the light guide plate is designed so that the light passes through to achieve a uniform brightness. Brightness is lower, as the light is emitted after the light guide plate reflective film reflection irradiation out, after the light guide plate so the luminous flux will have a certain loss. About 595*595 40W, specifications generally within 3200lm and relative to the same brightness, the cost is high, and the light guide plate life is very low, with low cost performance. But it's thinner, the thickness is within 15mm, suitable for part of the ceiling lower scene. The uniformity of luminous efficiency is low, up to 0.85, and there will be more obvious bright edges around if the production process is not handled well. High requirements for cleanliness in the workshop, and if not, the dust will lead to bright spots in the light guide plate; poor process control leads to a low yield rate.

Direct and side illuminated panel lights have their own advantages and disadvantages in-process and practical use, and the choice of which style depends on market demand and trends. So what material panel light would be a more cost-effective choice, based on price and performance? We take the direct luminous panel light as an example and talk about the advantages and disadvantages of the different materials used for each component and the points that need attention.

Advantages and Disadvantages of Each Component Material

Frame

The external frame of the panel light is mainly made of plastic or aluminium. Aluminium has better heat dissipation compared to plastic and can extend the service life of the light. In terms of the process of the 4 corners, aluminium materials are mainly used in two ways: splicing and welding. Although the cost of splicing is low, insufficient technology will produce splicing gaps, which will lead to the entry of dirty and the light leakage phenomenon, affect light efficiency and life. Most of the products on the market use aluminium welded edges. The frame is strong, with a good surface texture and overall beauty.

Frame processing requires attention.

If it is spliced, there must be narrowing the splice gap

If it is welded, the welding joints must not be too large

Diffusion Plate

Diffusion plates in the use of LED panel lights mainly play a role in blocking debris and light diffusion, so that the light is more uniform. The main materials of the diffusion plate are PC, PMMA, PS, PP. Early use of PMMA (acrylic) material, it has good light transmission, but the material is brittle and fragile, and the price is higher, so it’s gradually eliminated by the market. Later on, PC material appeared, but the market price is still high, mostly for high-end products. Based on the price and the effect of use, PS and PP are more cost-effective and are now widely used in the market. In addition to the material, its thickness is also a factor in the selection. As the direct light-emitting panel lamp beads are arranged on the substrate, its light efficiency is already very high. If the diffusion plate is too thin, it may lead to the internal beads obvious to see with poor aesthetics, and the soft light effect is poor. Therefore, a product with a thickness of roughly 0.8mm or more and a high degree of atomisation is required.

Light Panel

The direct panel light beads are evenly arranged on the substrate at reasonable intervals. Taking into account the heat dissipation factor, the aluminium substrate is generally used. From the point of view of its quality, it mainly depends on the thickness of the aluminium plate. There are the market 0.8mm-2.0mm ranging on the market. The thicker its heat dissipation effect is better, and naturally the price goes up. However, based on the cost performance, the general 1.0mm thick aluminium plate has a relatively excellent heat dissipation effect, and the cost is also in a generally accepted degree. In addition, LED lamp beads, adopts the use of encapsulation and other processes to protect the light-emitting chip. Basically, under the same parameters, the price between different manufacturers are also significantly different. It is a major factor in pulling apart the total price span among various suppliers. But the low price is not the only criterion for selection. Many factories can do the same parameter effect, but its service life, light decay length also weigh a lot. Thus, the balance of price and quality is the focus of value for money.

Driver

The driver for the luminaire is a key component to achieve the conversion of AC power into DC power. Generally speaking, the driver is divided into isolated and non-isolated models at the beginning. There exists a stereotype that isolation is safer than non-isolated and has longer service life. But in fact, if the non-isolated driver can be added with the corresponding anti-surge, anti-interference components at the front-end, the use of the effect may be better than isolated models, and the price is relatively more advantageous. At present, many countries are gradually changing their drivers to linear, but require voltage stability. If the isolated model considers reducing costs, you can do a single voltage or narrow voltage. Generally speaking, although the wide voltage meets more market demand, the price will be a little higher.

Base Plate

The base plate of the panel light is generally made of tin through the mould stamping, and the surface is laminated or sprayed with plastic. Relatively speaking, the cost of plastic spraying will be a little higher, while the effect of the process of lamination can achieve and spray almost, but there are cost advantages. Another impact on the price of the base plate is the thickness, the thickness of the base plate on the market varies between 0.2mm-0.3mm. Although the greater the thickness of the base plate will make the lamps look more solid, it has no absolute impacts on the actual use effects and service life of lamps, so a good balance of thickness is also an important factor in reducing costs.

Panel Light Selection Summary

In summary, the advantages and disadvantages of several key parts of the panel lights’ structure and materials have been clarified. To select a cost-effective panel light on the basis of material, we also need to pay attention to the material specifications, and select the appropriate specifications, to ensure the use of the effect and quality, and make a balance of prices.

Based on the actual use of scenarios and needs, aluminium welded frame, PS or PP material diffusion plate, 0.23mm thickness of iron plate laminated base plate, 1.0mm thickness of aluminium substrate with high-quality lamp beads, and the driver meeting demands of market voltage. This panel light program is currently more common on the market, ensuring the use of the effect and the cost with more advantages .

There is a big difference when choosing seemingly ordinary panel light. If you still have no idea, then might as well know this panel light. Homebest S4-PA6060 series panel light is made of high-quality aluminium material, with a thick frame that is not easily deformed, and it is rust resistant. The PS diffusion panel softens the light and enhances the uniformity of light transmission. The excellent sealing process with the frame prevents dust from getting on it and surface stains are easily removed with a soft cloth. High-quality SMD2835 LED beads for vivid colour rendering and high luminous efficiency. Sturdy chassis sealed structure, dustproof and durable. 100 lm/W high lumen output, 32mm slim design, and it can be perfectly embedded in corridor, office, supermarket and other multi-scene ceilings.

Details link: www.hbsocket.com (Detailed page for this model)