The Saudi SASO regulations on Restriction of Hazardous Substances (RoHS) are issued to ensure that the percentage of hazardous substances in electrical and electronic equipment and their spare parts on the market is lower than the regulations to ensure the protection of the environment and the health and safety of consumers.

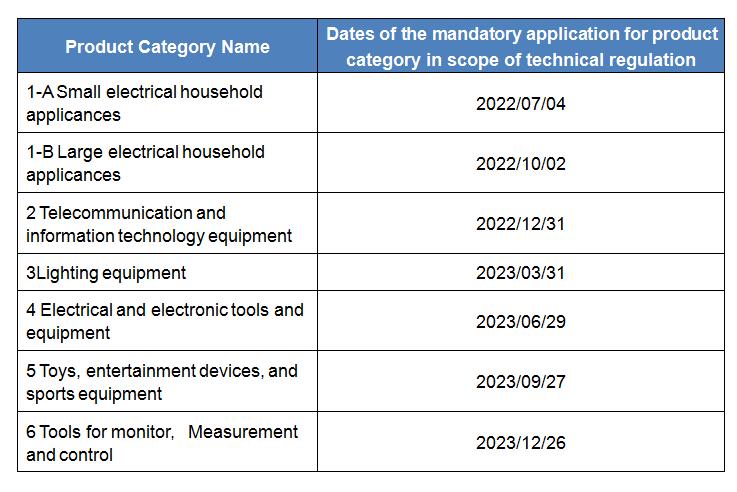

Saudi RoHS implementation plan and the specific phases

On 28 March 2018, Saudi Arabia issued notification /TBT/N/SAU/1048 to develop a draft technical regulation on the restriction of the use of certain hazardous substances in electrical and electronic equipment.

On 9 July 2021, the Saudi Standards, Metrology and Quality Organization (SASO) officially issued the Technical Regulation on Restriction of the Use of Hazardous Substances in Electrical and Electronic Equipment (SASO RoHS), which controls hazardous substances in electrical and electronic equipment and requires six categories of electrical and electronic products to undergo conformity assessment before they can enter the Saudi market. The regulation was originally planned to be mandatory from 5 January 2022, but SASO's latest notice dated 16 December 2021 extended the RoHS to 4 July 2022 for gradual phased implementation by product category.

1 - Household electrical equipment

①Small household electrical equipment to be implemented from 4 July 2022.

②Large household electrical equipment to be implemented from 2 October 2022.

2-Communication equipment to be implemented from 31 December 2022

3-Lighting equipment to be implemented from 31 March 2023

4-Electrical and electronic equipment and tools to be implemented from 29 June 2023

What importers and exporters should do to prepare

In fact, many importers and exporters were already preparing for the re-sourcing of raw materials, the improvement of production lines and the testing and certification of finished products when they received the notification in July 2021 that RoHS certification would be mandatory in January 2022, so for many manufacturers, the extension of the policy is just a matter of having more time to prepare.

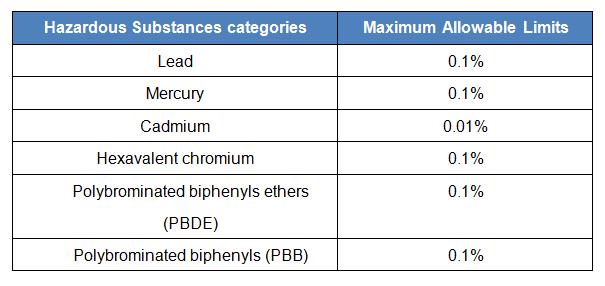

Restricted substances and control limits required by the new regulations:

If you are just about to start the rectification process according to the RoHS requirements, you need to note that the RoHS certification covers not only the whole product, but also the components, raw materials and packaging parts used in the production of the whole machine, and even the tools used to assemble the product, which relates to the whole production chain. In particular, electrical and electronic products in the production of a large number of solder, and packaging boxes printed with ink all contain lead and other harmful heavy metals. So if the final product is to pass the RoHS hazardous substances test, then you need to trace the raw materials, the tools used to assemble the product on the production line, the packaging, etc.

A basic step is to check the existing raw materials and components one by one and to communicate with suppliers to confirm that these materials comply with the RoHS standard. Screening suppliers of materials that do not meet RoHS requirements and selecting new suppliers to re-source materials that are free from hazardous substances. Of course, material prices may go up, so manufacturers can stock RoHS-certified materials in separate piles from normal materials, and for markets and customers without RoHS certification requirements, choose materials with price advantages.

The next step is the rectification of the production line. All machines, tools, storage baskets, transport equipment, etc. that are used in the manufacture of products or that come into contact with them must be assessed for hazardous substances to ensure that they do not come into contact with them during the entire production process. Of course, many of the machines and equipment need to be replaced at a considerable cost.

Also, pay attention to the packaging printing problem. One of the most important aspects of RoHS testing is the testing of printing inks, and SONY's digital cameras already state on the box that the product is soldered and printed with lead-free inks.

After that, the product will be sent to the sample certification, as long as the SASO accredited third-party notary laboratory can provide similar services for enterprises, according to the ISO/IEC17067 standard specification that "conformity assessment product certification basis and product certification scheme guide" provisions for testing, analysis, which lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls (PBB), polybrominated diphenyl ethers (PBDE) and other six If they comply with the RoHS Directive, a RoHS conformity report and certificate will be issued. If they do not, another product that meets the requirements will have to be found as a substitute.

Impact of Rohs certificates on applications for other conformity certifications and local markets

RoHS certification will not only have an impact on other certifications in Saudi Arabia but will also affect import clearance procedures and marketing.

Before registration with SABER PCOC, Gulf Technical Regulations for Low Voltage Electrical Equipment, IECEE and other relevant electrical technical regulations, a RoHS certificate must first be obtained. The CB certificate can only be issued once the RoHS and Low Voltage Electrical Equipment and other relevant electrical technical regulations have been approved.

Upon import clearance or during marketing, customs and market surveillance authorities have the right to take random samples of products and submit them to laboratories to determine compliance with the RoHS technical regulations. Once a product is found to be non-compliant, the relevant authorities may request the implementation of measures such as withdrawal, destruction and restriction of the product, and impose appropriate penalties.