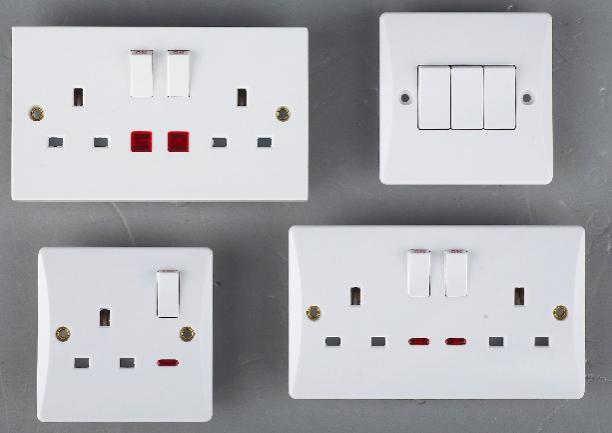

Wall switches and sockets commonly found on the market and commonly used in life, are generally divided into plastic, wood and metal switches, according to the panel material. Importers need to know the sales market's preference for these three materials before planning a purchase, as well as the positioning of their own brand. As the price points of different materials for switches and sockets are different, the degree of popularity in different markets is also different.

1. Understand basic information of the three materials

a. Plastic series

Plastic switch materials can also be divided into PC material, PP material and ABS material.

PC material is also called bulletproof rubber, which has the advantages of high strength, strong impact resistance and strong anti-ageing ability. Moreover, the surface of the panel frame made of PC material is smooth and delicate. It does not fade easily and is resistant to UV radiation. In addition, it has excellent resistance to high temperatures, with an ignition point above 850 degrees and automatically extinguishes within 20 seconds of leaving the fire source. However, the choice of PC material is to pay attention to the distinction between new material and old material. New material to make the finished product surface colour and bright, structural toughness, but the price is high. The finished product made of the old material is affordable, but the surface colour is yellow and broken.

PP material is less expensive than PC material but is less resistant to high temperatures and flame retardancy. Otherwise, it is roughly the same and will usually be used as a replacement in price terms.

ABS is acrylic, and its processing process is more mature. It is a class of material used more in the early days of wall switches. It is characterised by good dyeability and low price, but ABS features poor toughness, weak impact resistance, short life expectancy and cracks on the surface of the product after long-term use and yellowing of the surface. Secondly, and most importantly, the general ABS material does not meet the standard 750°C flame retardant requirements, and ABS material with flame retardant effect is more expensive than PC. Thus, now the switch rarely uses ABS, unless it is a low-priced positioning product, and the market has no clear flame retardant requirements.

b. Bakelite series

Bakelite is a non-toxic, odourless, hard, scratch-resistant thermosetting plastic with good self-extinguishing, arc-resistant and electrically insulating properties. It has good self-extinguishing, arc resistance, electrical insulation and corrosion resistance, and is often used as a panel frame and base material for switches. The surface of the Bakelite series is relatively smooth to the touch, but after many years of use, there will be visible scratches and a strong sense of burr to the touch. The price of bakelite is generally between plastic and metal and is a more traditional and classic panel material in the minds of many consumers.

c. Metal series

Metal wall switches and sockets have become popular in Europe and the USA in recent years. Most of the panels are made of iron, with the surface painted or plated. The surface is electroplated and brushed, with a variety of colours available, such as mirror copper and brushed chrome, with black inserts or white inserts, for a more luxurious and textured appearance. The metal itself is stronger and will not break during installation even the screws are tightened too much. In the long run, metal is more durable and less prone to ageing.

2. Difference among three styles from the appearance, price and lifespan

a. Appearance

When looking at these three types of material switches from the outside, plastic is more malleable in appearance and can be designed in a more varied way. If you choose a good quality plastic, both the surface gloss and the tactile feel will be excellent. Bakelite switches have a thicker feel and are less design-intensive, but many classic models are made of bakelite. Metal panels, on the other hand, are more suited to a more atmospheric, high-class atmosphere. The brushed and electroplated surfaces are expensive but attractive.

b. Price

Evaluating these three styles of switches from the most intuitive price point of view. For the same configuration of a 13A British Standard socket with indicator light and a double pole switch, the price of bakelite is 30% higher than plastic, while a metal one is 4-5 times more expensive than a plastic panel. However, the price also depends on the positioning of the customer's brand, with brands in the low and mid-range choosing plastic and wood. And high-end brands when supplying the other two categories, also sell metal models to reflect quality, and to attract a higher consumer base.

c. Lifespan

The lifespan of a wall switch is mainly reflected in the number of times that the button is pressed, the number of times the socket is plugged in and out, the appearance of the panel frame and the corrosion resistance. The quality of the button and socket holes also relates to the intermediate module and copper parts, so no reference is made. In terms of the appearance and corrosion resistance of the panel frame and base, panel frames made from plastic are prone to scratches and are less resistant to compression and fire than Bakelite. It looks like that metal is stronger, and the overall pressure resistance will be better than plastic and bakelite. Good surface plating and brushing process can effectively achieve the effect of corrosion resistance.

3. Different demands in different British Standard markets

The British Standard switch refers to the triangular straight socket, which is mainly used in the UK, Saudi Arabia, UAE and other Commonwealth markets. In addition to those well-known brands on the market, most of their supply categories contain all materials, for some small and medium-sized importers and retailers, corresponding to the sales market to choose the matching materials and styles of switch and socket is very important.

Although Saudi Arabia, as an oil kingdom, has a very luxurious feel, the local market still prefers simple styles. Plastic and bakelite are more popular, with a higher requirement for glossy surfaces and a preference for larger button sizes at present. However, the technical regulations and certification requirements for wall switches and sockets in Saudi Arabia are relatively high, such as the new SQM and RoHS, which require the importers' attention in advance.

The local market in Dubai is mostly suppliers of well-known brands, and the market is very competitive for some importers who do their own branding, and most consumers will choose branded models. So many Dubai importers are doing re-export trade to Africa. Most of the products are made of bakelite and plastic who has not high appearance requirements, but require affordable prices. So importers who choose to re-export to Africa need to be competitive in price to increase sales.

The UK is one of the main target markets for British Standard switches. As a developed country, the pursuit of quality and appearance of products is simultaneous. British consumers prefer bakelite and metal wall switches and sockets, with bakelite being durable and safe, and metal being high-end with a strong sense of design. If importers are to supply switches and sockets for the UK market, they need to agree with a competitive cooperation target with factory manufacturers, not only for new styles but also for competitive prices. 70% of the switch and socket in the UK market are imported from China, with manufacturers mostly concentrated in Fuyang, Zhejiang and Shenzhen, Guangzhou, because the price of metal series is generally high, and it is possible to compete with well-known brands if your brand can have a price advantage.

In addition, some other countries, such as Bahrain, have a preference for plastic, with a small proportion of bakelite. Yemen also has a preference for plastic, but consumers prefer more fancy looking styles. In Kuwait, the local market is dominated by bakelite styles. Qatar supplies more in bakelite and metal series.

It is not difficult for an importer to enter a market, but it is worth thinking about the long term and sustainable development. Understanding the material categories, the advantages and disadvantages of different materials and the sensitivity and preferences of the target market before starting to supply the market is the cornerstone of success.