The LED flat panel light is thin and light, evenly and softly lit, with a simple and generous appearance, and is favored by the majority of Middle Eastern consumers because of its unique advantages. Flat panel lights are widely used in kitchens, bathrooms, balconies and offices.

However, LED flat panel lights have high requirements for technic and quality. As the products on the market are uneven, it is very important for importers to know how to choose the models and how to check the quality of the products.

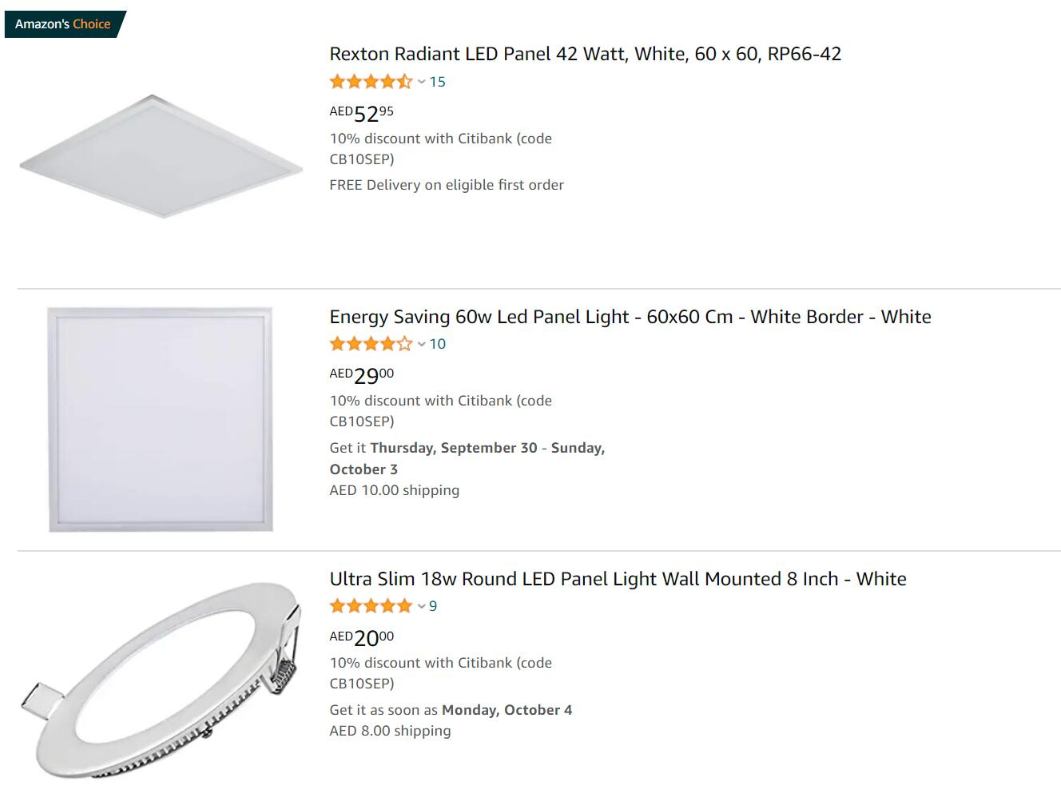

Firstly, the most common size of flat panel light on the market is 60x60CM, as can be seen from the sales data on Amazon Middle East.

Depending on the installation method, there are two main styles: ceiling-mounted (open-mounted) and recessed (concealed). The surface mounted style only requires the installation of the surface mounted conversion frame with screws and then the connected power supply body is stuck into the conversion frame to complete the installation. The recessed style requires the mounting conversion frame to be snapped into the ceiling and then the connected power supply lamp body to be snapped into the conversion frame to complete the installation. Judging from Amazon sales figures, the concealed version is more popular with the market.

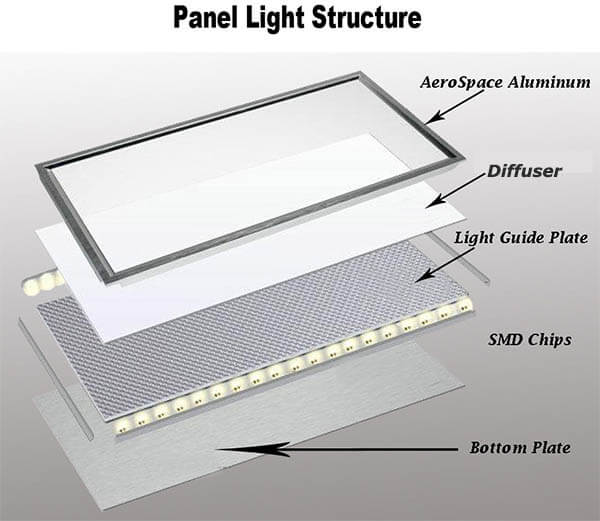

Next, let's look at the components of the panel light and its materials.

Now for a dismantling of the panel light, we can see that the structure of the panel light has the following main parts:

Frames

Heat sinks

Light guide plates

Drive

Frames

The frames on the market today are mainly made of aluminum, and the process is based on aluminum extrusion molds, a process with low upfront costs. Its counterpart is the die-casting process, but the cost is much higher. Importers who do not understand these 2 processes can understand that the aluminum extrusion mold is equivalent to squeezing the material like toothpaste, after passing through the mold into a certain kind of long fixed shape, and then cutting the long aluminum strip later on, while die-casting can be understood as the mold of the cover stamp, directly using the mold to die-cast the finished product on the material, from the process, the output of the latter is lower than that of the former. The basic models of flat lights, therefore, are framed using the first, more cost-effective process.

From the data on Amazon's Middle East site, the mainstream size of the frame is 60x60CM, and it is easy to see from the consumer reviews that this size of flat panel light is commonly used in bathrooms and kitchens. Therefore, when choosing the style of imported flat panel lights, different sizes are hot in the market and need to be planned and adjusted according to the local market situation.

Diffusers

The role of the diffuser is to spread the light evenly from the light guide, and also to play a role in blocking out the network.

Diffusion panels on the market are mainly made of acrylic or PC.

Compared to the two materials:

The market share of acrylic is higher.

Acrylic is a brittle material; anti-ageing properties are also weak. Compared to the PC, its toughness is better.

The cost of acrylic is lower and the cost of PC is higher.

Acrylic has a higher light transmission rate than PC.

By looking at the material descriptions above Amazon, acrylic diffusion panels are predominant. Suppliers in the choice of material, should pay attention to the difference between the comparison of different samples, and choose the right diffusion board material.

Light guide plate

If you consider LED flat panel lights as a whole, then the light guide is the heart of the whole.

In many cases, we will find that the flat panel light has a situation where the middle is bright and the sides are dark, or the incoming light side has a bright edge but the middle is dark, or commonly the whole light is bright and dark in different ways. Why is this the case? Because a large part of the light effect of the light guide is in the design of the dot, followed by the use of the plate. The role of the mesh is to use the principle of total reflection to change the line light of the LED into surface light. It can also be understood in this way: the light guide is a combination of acrylic (PMMA), the material of the board itself, and dots. LED flat panel lights sold on Amazon are generally covered by a 5-year warranty, so the light guide, as a key part of the product quality, needs to be given attention by importers.

Drivers

There are 2 types of drive for products, isolated and non-isolated. Isolated means that the input and output are electrically connected via a transformer, so the transformer conversion process is: from electricity to magnetism to electricity. There is no grounding, so there is no risk of electric shock. Non-isolated, on the contrary, the input power is added directly to the LED load after the voltage is raised and lowered, so there is a risk of electric shock.

But non-isolation also has its advantages. Due to the less energy loss of the variable voltage, the efficiency can generally reach more than 90%, while isolation can generally only reach 85%. Non-isolated circuits are very sensitive to surges and have poor suppression capabilities. So in bulk shipments, the return rate of non-isolated will also be higher than isolated, and the reason is that the power supply is fried. So, in many non-isolated products drive, anti-surge varistors essential, generally no pressure sensitive can give a warranty, the feasibility is not high.

Importers, if your product needs to pass safety certification, then the non-isolated structure will be more trouble to pass the test. It is recommended to choose an isolated structure.

The above is an analysis of some key components of some attention with LED flat panel lights. Online data, can well help importers friends to analyze the local market demand for products, as well as the rising trend of the product sales opportunities to grasp. While paying attention to some key structural factors, more analysis of the changes in the market. Feel free to write to us for the latest product advice as well.