There are so many different types of wall switches on the market that it can be difficult to tell if they are of good or bad quality just based on the pictures on the website or their appearance. Of course, the well-known brands are more reliable, but some niche brands also offer good quality and safety guarantees. In addition, the different price points and ranges of wall switches will also have a bearing on quality. The safety and durability of a wall switch are both issues that we should be concerned about. How can we judge the quality of a wall switch when we are shopping for one? We can analyze the difference between different quality wall switches mainly from the point of view of their appearance, material and packaging.

The appearance of wall switches

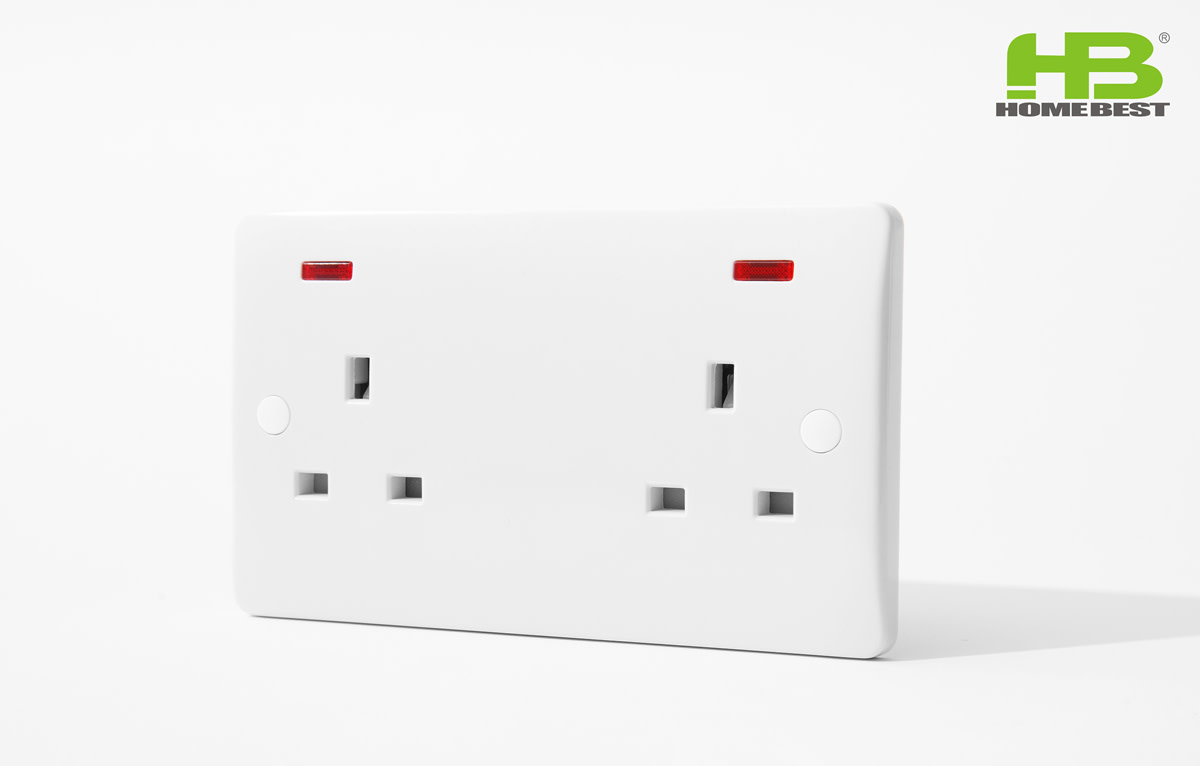

Firstly, when we get a wall switch, we can start by looking at whether its surface is smooth as new, whether there are any wear and scratches, whether the color difference will be too great and whether the switch as a whole has a textured feel. Touch and press the switch buttons to see if they are smooth or jammed. Generally speaking, a good quality wall switch will not have too much color difference and will have a good texture and feel very smooth to use. A qualified switch socket has a finely finished shell panel, no burrs on the shell and jack sides and a symmetrical and uniform jack size, while a poor-quality socket has a roughly finished shell.

At the same time, we can also judge the adequacy of the materials used in a switch socket by its weight. Sockets that meet national standards generally have more copper wires, thicker copper sheets and tighter plastic shells, so they are heavier in weight, while unqualified sockets, which cut corners, will obviously feel much lighter. So, we can try to weigh the wall switch to estimate whether it is genuine.

The material of the wall switches

We can also start from the switch material to analyze, mainly for the panel material, back seat material and internal material.

1. Panel.

At present, the commonly used materials for panels are PC material, rubber wood and ABS material.

1)PC material: impact resistant, heat resistant, flame retardant and insulating, it is a more excellent material for switch panels.

2)Bakelite/Urea: with the advantages of good flame-resistance, easy coloring, stable product size and bright color, it is an increasingly popular material for manufacturing switch and socket panels.

3)ABS material: its heat resistance and impact resistance are far less than PC and electric jade powder, and the surface is prone to yellowing and cracks in long-term use.

2. Backset.

The material used for the back base is imported reinforced nylon and recycled PC material.

1)Imported reinforced nylon: flame retardant, insulation is better, corrosion resistance, impact resistance, and high temperature does not deform, to ensure that the internal components never fall off.

2)Recycled PC material: weaker impact and heat resistance, easily deformed.

3. Internal materials

1)Switch carrier material - shrapnel

The main material used is copper, mainly brass, tin-phosphor bronze and red copper.

Brass: bright yellow, hard texture, slightly less elastic, medium conductivity

Tin-phosphor bronze: reddish-yellow, hard, flexible and with a better conductivity than brass

Red copper: purplish red, slightly soft, good elasticity, higher conductivity

Ordinary socket brass is 0.4-0.5mm, easy to bend, while good socket brass is 0.7mm thick, difficult to bend.

2)Switch contact material.

What are switch contacts? When we press the switch, we can all hear the sound, which is produced by the contacts, which are two metal pieces or metal balls that produce the sound. If the contacts are not safe enough, they are prone to arcing, causing a short circuit in the switch and a danger. Therefore, the material of the switch contacts is particularly important. The two main materials that are popular on the market at present are pure silver and silver alloy.

Pure silver has a low resistance, soft texture, low melting point, easy to oxidize, easy to produce arc, burn the wire or switch components, resulting in poor energization. Silver alloys, on the other hand, have a low resistance, wear-resistant texture, high melting point and oxidation resistance, and are superior to pure silver in terms of overall performance.

Packaging for wall switches

Let's look at the packaging again. Generally, the packaging of qualified sockets must be complete with manufacturer, product information and certification, and the materials used in the packaging must be solid and have a sense of design. Some unqualified sockets have a more rudimentary packaging and are missing basic manufacturer and product information, especially production dates.

So, we can simply judge the quality of the wall switches we buy by their appearance, materials and packaging. A wall switch that has a simple, textured appearance, is made of good, thick materials and is well packaged will greatly reduce the risk of the switch being used and increase its lifespan.

For more information, follow the Homebest website: www.hbsocket.com