In general, different markets have different preferences for different types of lighting. Some markets sell better with bulbs, and some markets have a wider range of applications for downlights, while 600*600 engineering panel lights seem to be common in most countries. For wholesalers and importers in the LED lighting category, the 600*600 engineering panel light is a good choice to open up new markets.

So, when purchasing this panel light, the following points do you notice?

I. Engineering panel light parameters

1. Light-emitting mode

Circulation of engineering panel lights on the market according to the light-emitting mode is divided into backlit and side-lit two. Backlit panel light uses the light-emitting angle of the LED beads to a reasonable spacing evenly arranged on the substrate plate, with the diffusion plate and the installation height to achieve the ideal light effect. The process requirements are relatively simple, and the brightness is high and uniform, but the size of the lamp body is thicker. The side-lit panel has a light guide plate that the backlit panel doesn’t have. The LED beads are inlaid around the panel, and according to the layout of the LED beads and the angle of the beads, the light guide plate is designed so that the light passes through to achieve a uniform brightness. The cost is high and the process is demanding, but the size is thinner.

2. Technical parameters

As with general LED lighting, the purchase of engineering panel lights requires clarification with the supplier on power, luminous efficacy, color temperature, voltage and frequency range. It is worth noting the voltage and frequency range of this parameter. Although the engineering panel light is common in many markets, different countries specify the voltage and frequency applicable range is different. For example, most European member states require 220-240V 50/60Hz, Saudi Arabia can be a 127-240V 60Hz range of voltage. It is also necessary to clarify the requirements of wide voltage and narrow voltage, wide voltage driver price will be higher than the price of narrow voltage drive, but the application range will be broader. Of course, you cannot just pursue the wide voltage, you need to meet the relevant certification requirements.

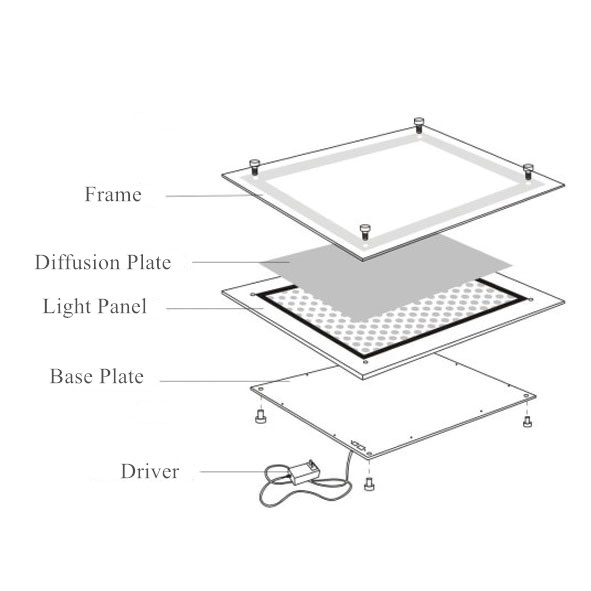

3. Material of each component

In the evaluation of the engineering panel light parts material is, mainly refers to the frame, diffusion plate, light panel, driver, base plate, light guide plate (only side-lit panel has) these parts. The type of material and thickness of the components will affect the luminous efficiency, heat dissipation and service life of the panel light, but of course, the more direct impact is the cost and price. So instead of taking price as a single reference target, assessing the price through the material of each component is one of the key points in purchasing engineering panel lights. How to choose different component materials to balance the quality and cost of engineering panel lights, you can refer to the article "How to choose a cost-effective LED panel (600*600)".

II.The difference between 595 and 600 panel lights

We generally talk about 595*595 and 600*600 when it comes to engineering panel lights. The difference between them is also really just a size difference. In foreign countries, many customers will default to these two calls referring to the same product, although most foreign requirements of the actual size are 595 * 595, for the aspect of calling, many are directly said to be 6060 or 600 * 600 panel lights. The reason why there are two sizes is that most integrated ceilings in China are 600*600 as a standard specification.

So, if you are purchasing an engineered panel light from your supplier, make sure you pay attention to the actual size of that panel light.

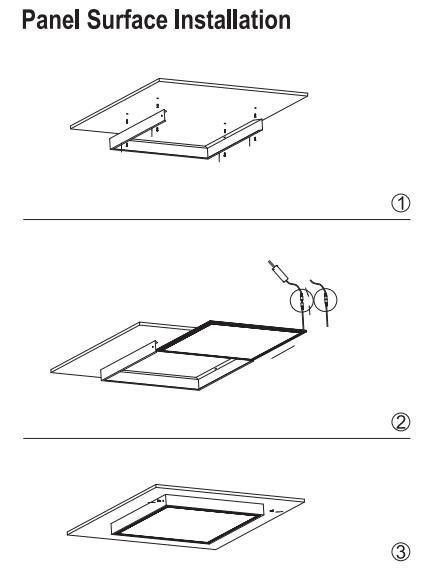

Of course, a 5mm difference will not necessarily affect the actual use, but it is likely to limit how it can be installed, as the dimensions of your local integrated ceiling are standardized and a 600mm panel light will certainly not fit into a 595mm ceiling hole. Also, other ways of installing the fitting kit will need to be matched. In the surface installation method, the 600mm outer frame needs to be a little larger than the 595mm one.

III.The choice of accessories parts

The use of accessories parts is because the engineering panel light has a multi-use installation method. Depending on the ceiling material and the desired installation effect, it may be necessary to match different accessories to complete the installation.

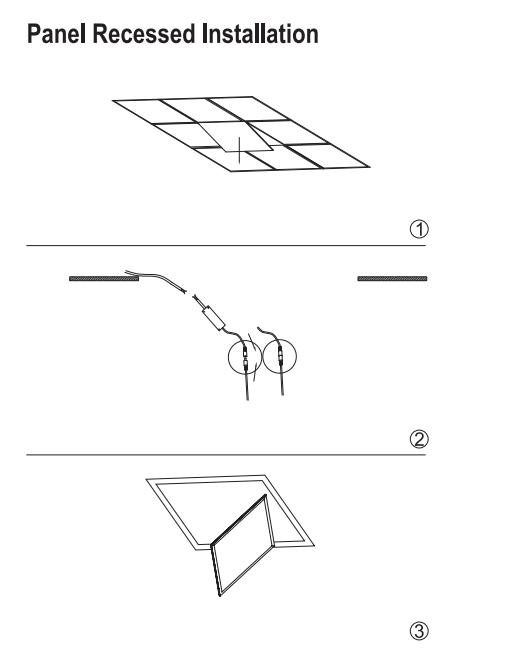

Firstly, the simplest way of installation is to place the panel lights directly on the pre-determined openings in the ceiling without any other accessories. This method is generally suitable for standard integrated ceilings, where each ceiling panel is of the same standard size. After the wiring connection is completed, the engineering panel light is directly fed into the opening out, the angle is adjusted and it is placed smoothly on the baffle.

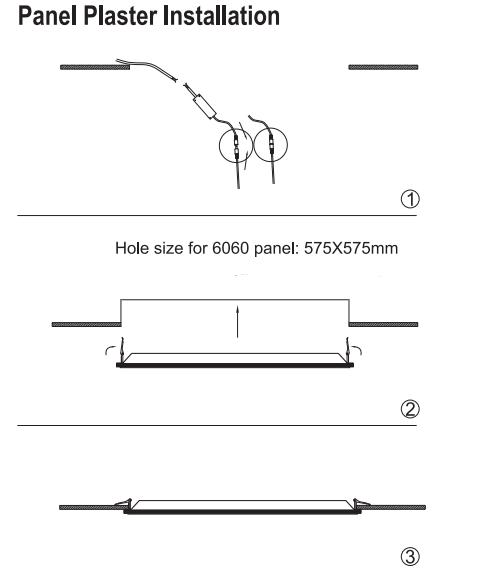

The second suitable scenario is if the ceiling is not specifically integrated and needs to be re-opened, then the size of the opening needs to be slightly smaller than the size of the panel and 2-4 spring clip fittings are required. After the hole is opened and the wiring is connected, the panel light is placed at the hole after the spring clip is plucked up at the same time, the spring clip is released and the spring clip is steadily stuck to the inner panel of the ceiling while the panel light achieves a recessed installation effect.

The third type is for ceilings that are not easy to re-open and can be installed in a surface way, using an outer frame fitting. It is necessary to first fix three sides of the frame to the ceiling, connect the external wiring, move the panel light into the frame, and finally fix the fourth side of the frame. This is one of how the project panel light can be installed surface.

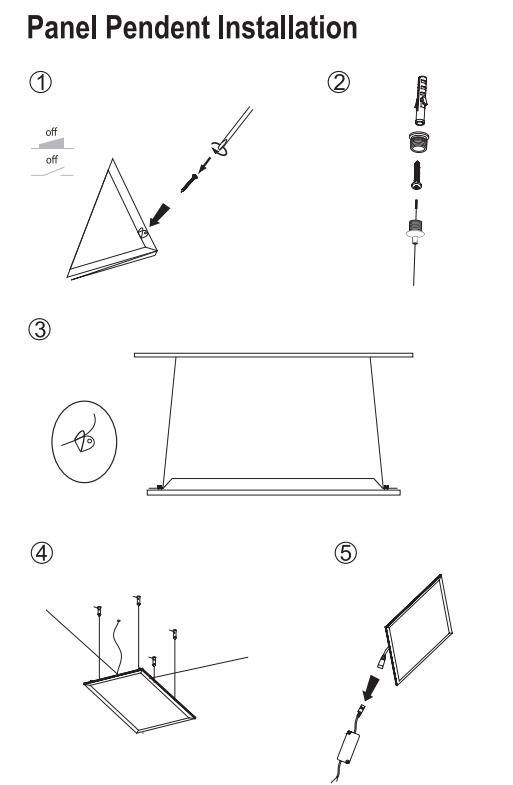

The fourth and another way of surface installation is to use the suspension method. It is necessary to fix the clips in the four corners of the panel light and then use a strong wire rope to suspend the panel light below the ceiling. This is a more modern and design-oriented way of installation.

The importer, therefore, needs to consider the needs of the end-consumer group further when purchasing the panel light and accordingly consider whether it should be accompanied by these accessories. Of course, for ease of operation, these accessories can also be sold as a separate item and sold with the actual requirements when the customer purchases the panel light.